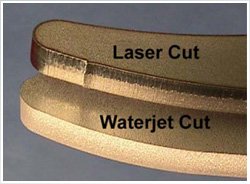

Comparative Cutting

Waterjet Cutting Comparison With Other Methods

Waterjets can cut any solid material including stone, tile, glass, metal, foam, rubber, plastic, and food. When compared with plasma, laser, and edm – waterjet cutting has distinct advantages.

WATERJET vs. Plasma vs. Laser vs. EDM

In addition to no heat-affected zone, the benefits and applications for waterjet technology are limitless and ever-expanding. In comparison to other cutting technologies:

As the grid above illustrates – and the image to the right shows, waterjet cutting technology has clear advantages over other cutting methods.

Green Benefits

Waterjet cutting is a cold-cutting process that eliminates slag deformation and dross waste – unfortunate effects found in plasma and laser cutting processes.

Additionally, both the garnet used in abrasive cutting as well as the water are recycable.